Turnkey Full Automatic Liquid Filling Production Line

Verwendbare Flasche: 1-500ml

Produktionskapazität: 30-40 Flaschen/Min., 60-80 Flaschen/Min., kann je nach Kundenwunsch angepasst werden.

Spannung: 220V 50Hz

Leistung: 2.0KW

Luftverbrauch: 0,8-2m³/h 0,3-0,8Mpa

Gewicht: 500KG

Abmessungen: Abfüllmaschine 2000*1250*1700mm, andere Teile optional.

Beschreibung

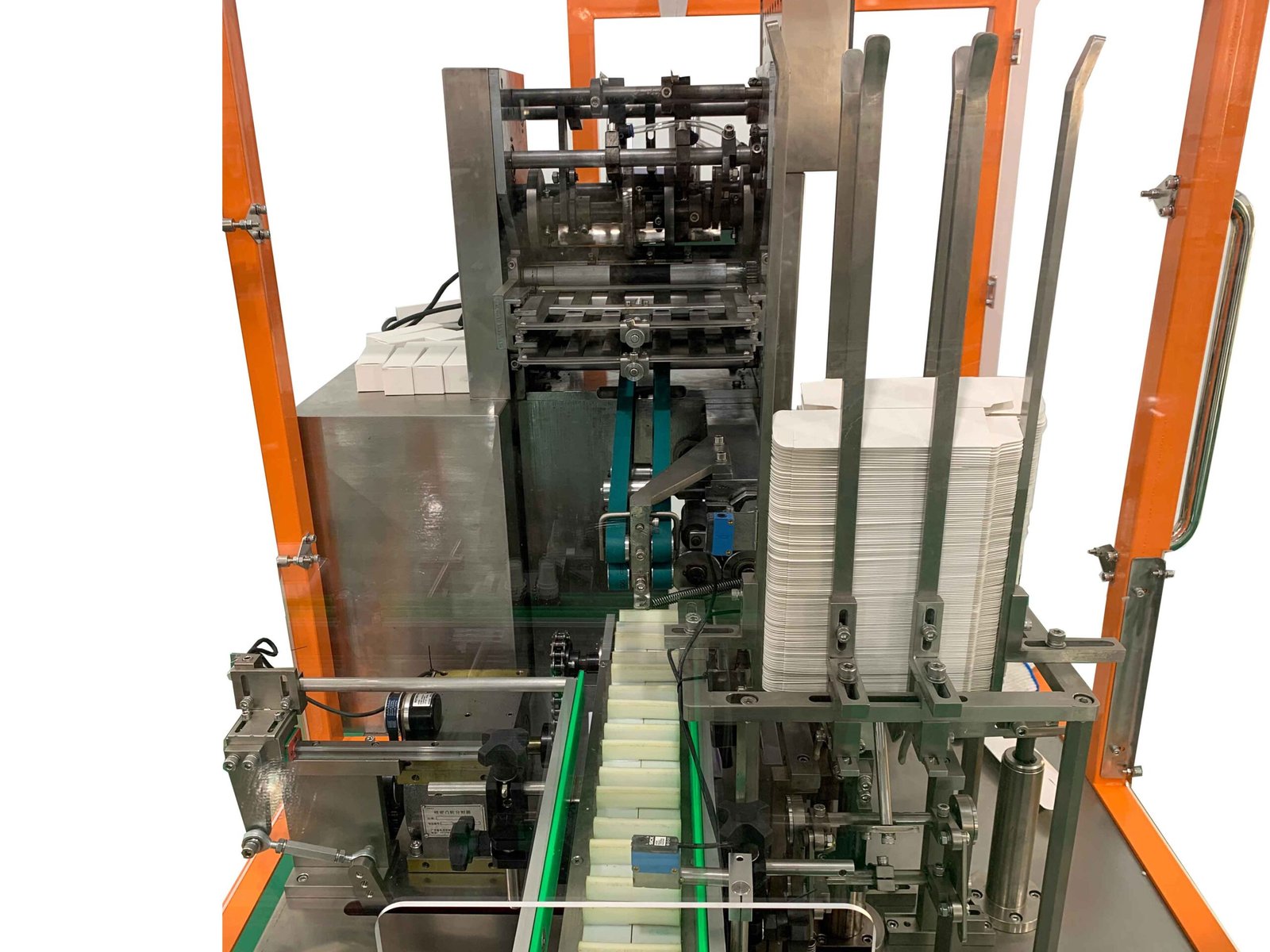

The Fully Automatic Liquid Filling, Capping, Labeling, and Boxing Production Line is an integrated and high-efficiency packaging solution widely used in pharmaceutical, cosmetics, food, and health product industries. This modular production line seamlessly combines liquid filling, cap tightening, labeling, and boxing into a single streamlined process. Controlled by a PLC system with a user-friendly touchscreen interface, it offers intelligent parameter adjustment, stable performance, and real-time monitoring. The entire system is customizable to suit various bottle shapes, sizes, and output requirements, making it an ideal choice for automated, large-scale production.

Merkmale:

- Fully automatic process from filling, capping, labeling to boxing, reducing labor costs and improving productivity.

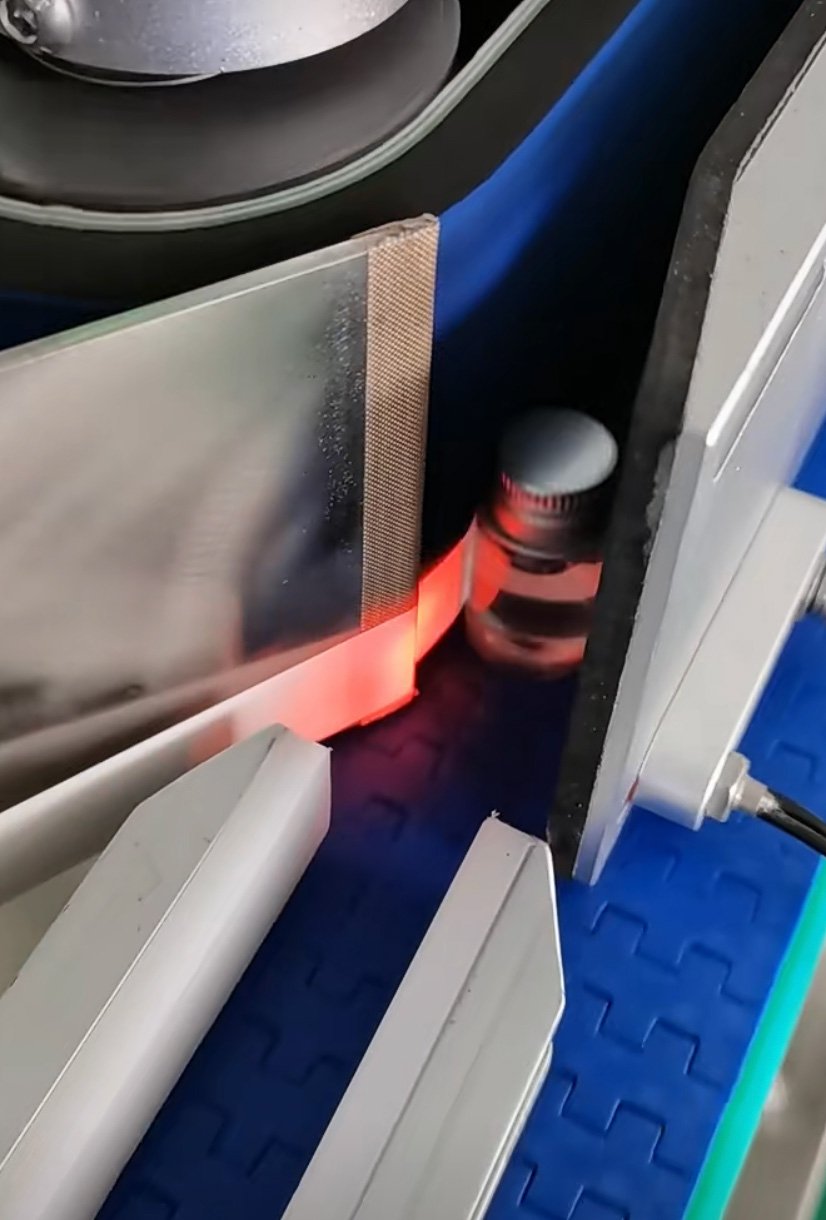

- Equipped with high-precision peristaltic or piston pumps, ensuring precise filling with no leakage or waste.

- Suitable for a wide range of bottle types and sizes. Quick mold change and parameter adjustment enable multi-product and batch production.

- PLC controlled with touchscreen, user-friendly operation, flexible parameter settings, multiple languages optional.

- Modular design with small footprint, stable line coordination, and easy maintenance.

- Entire machine made of SUS304/316L stainless steel, corrosion-resistant and easy to clean, meeting hygiene standards for pharmaceuticals, food, and cosmetics.

The production line equipments consist: bottle feeder, bottle unscrambler, bottle washing, filling, capping, labeling, expire date printing, foil sealing, counting, bottle boxing, sterilizing dryer, etc.