Línea de producción de botellas de solución oral de 30ml-150ml

Applicable bottle: 30ml-150ml

Capacidad de producción: 30-50 botellas/min, 60-80 botellas/min, puede ajustarse según los requisitos del cliente.

Precisión de llenado: ≥98%

Tensión: 220V 50Hz

Potencia: 2KW

Consumo de aire: 0,8-2m³/h 0,3-0,8Mpa

Weight: 500KG

Dimensions: Filling machine-2000*1250*1700mm, others parts optional.

Descripción

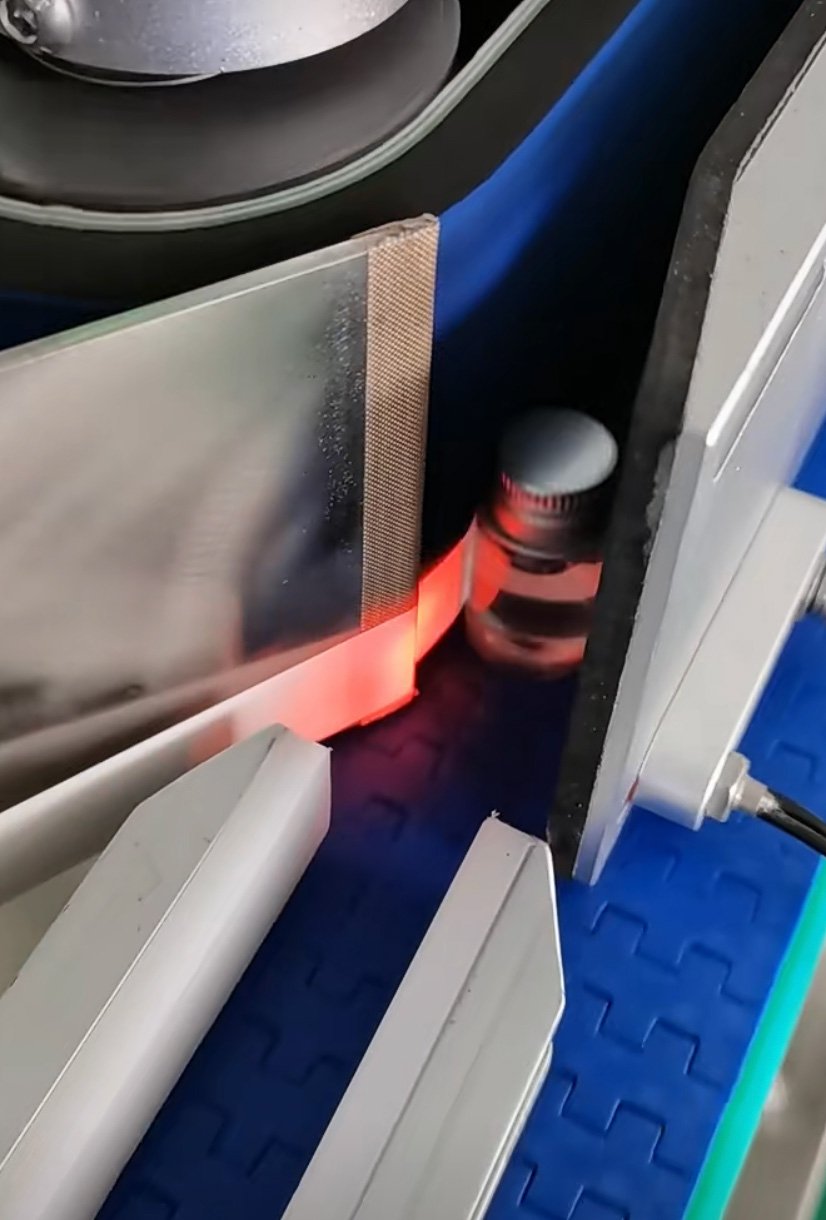

The Oral Liquid Filling Production Line is specifically designed for the efficient filling and sealing of oral liquid bottles, typically ranging from 30ML to 150ML. The line integrates multiple key processes, including automatic bottle feeding, liquid filling, cap placement, capping, and finished product collection. It adopts PLC control and peristaltic pump filling to ensure high accuracy and consistency. Equipped with an electromagnetic vibration cap feeding system and a rotary positioning mechanism, the line ensures smooth, stable operation. Widely used in the pharmaceutical, health supplement, food, and chemical industries, this production line is built in full compliance with the latest GMP standards, offering high automation, minimal human intervention, and strong reliability.

Características:

High Precision Filling

Equipped with peristaltic pumps to ensure accurate, drip-free filling.

Fully Automatic Operation

Automatic bottle feeding, filling, inner plug insertion, capping, and labeling for continuous production.

User-Friendly Interface

Smart PLC control with a responsive touch screen; easy to operate and adjust, multiple language set optional.

GMP-Compliant Construction

Made of SUS304 and 316L stainless steel, fully compliant with the latest GMP standards.

Modular Design

Can function as a standalone unit or be integrated into a complete production line.

Wide Application

Suitable for pharmaceutical, nutraceutical, food, and chemical products in small-dose liquids.

Personalizable

Moldes fáciles de sustituir, adecuados para diversas capacidades de producción de botellas.

Otros equipos adecuados para las líneas de llenado: alimentador de botellas, clasificación de botellas, lavado de botellas, etiquetado, taponado, sellado, recuento, impresión de fecha por inyección de tinta, encajado de botellas, secadora esterilizadora, etc.