Pharmaceutical Vial Bottle Filling Production Line

適用ボトル:1~50ml

生産能力:30-40ボトル/分、クライアントの要件に応じて調整することができます。

電圧: 220V 50Hz

パワー: 2.0KW

空気消費量0.8-2m³/h 0.3-0.8Mpa

重量: 500KG

次元:2000*1250*1700mm の任意他の部品。

説明

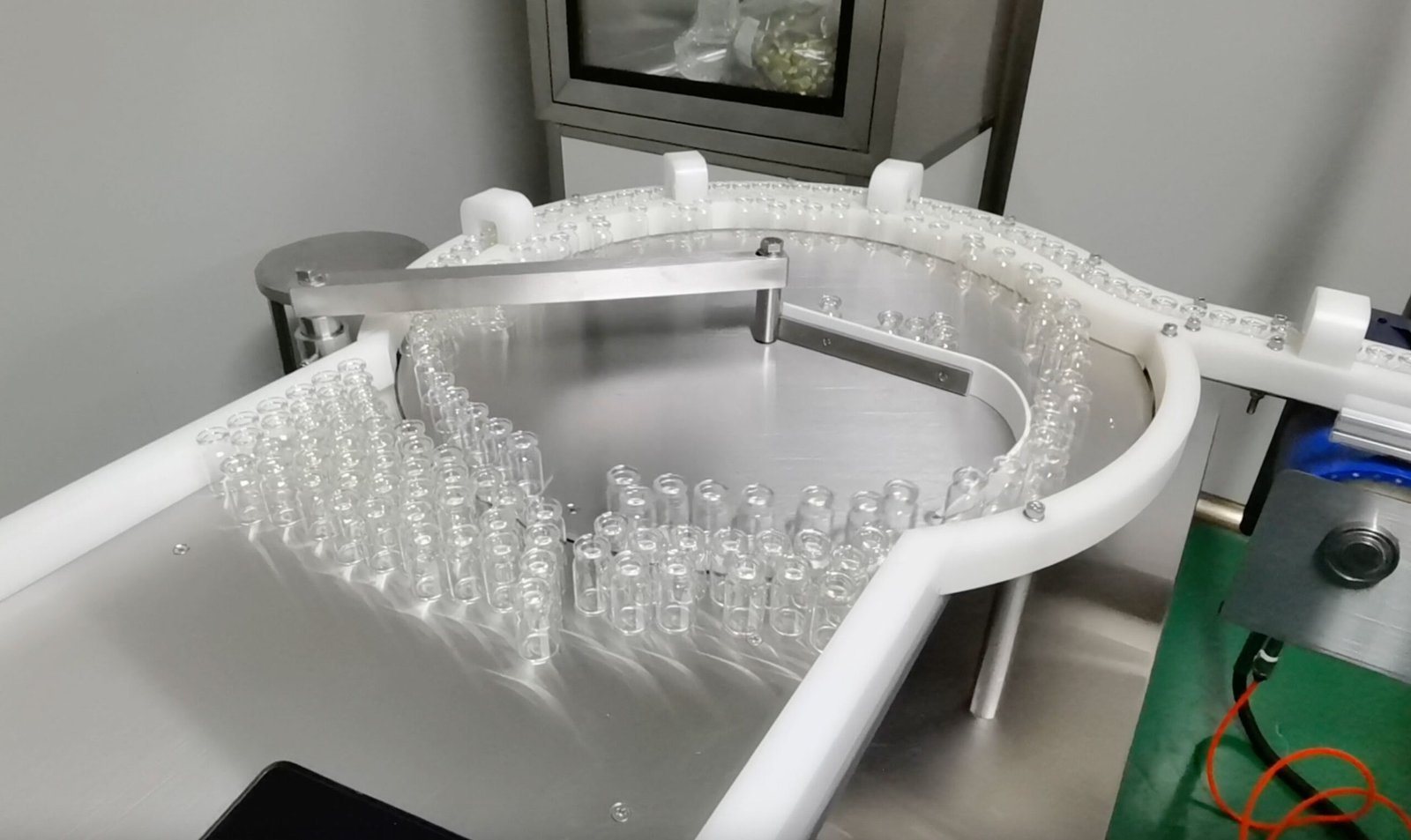

The vial bottle filling production line mainly consists of an automatic bottle washing machine, a tunnel sterilization oven, a vial filling and capping machine, a labeling machine, and other equipment. It adopts PLC control, touch screen operation, and peristaltic pump filling, ensuring high filling accuracy. The entire production line is manufactured in full compliance with the GMP standards and is widely used in the pharmaceutical, food, healthcare, and chemical industries.

特徴

- 高品質のカムインデクサーにより、充填、ストッパリング、キャッピングの正確な位置決めが可能。

- 高精度で簡単な操作のためのPLCタッチスクリーン制御で充填ペリスタポンプ、 複数言語セットオプション.

- 周波数変換制御により速度調整が可能。

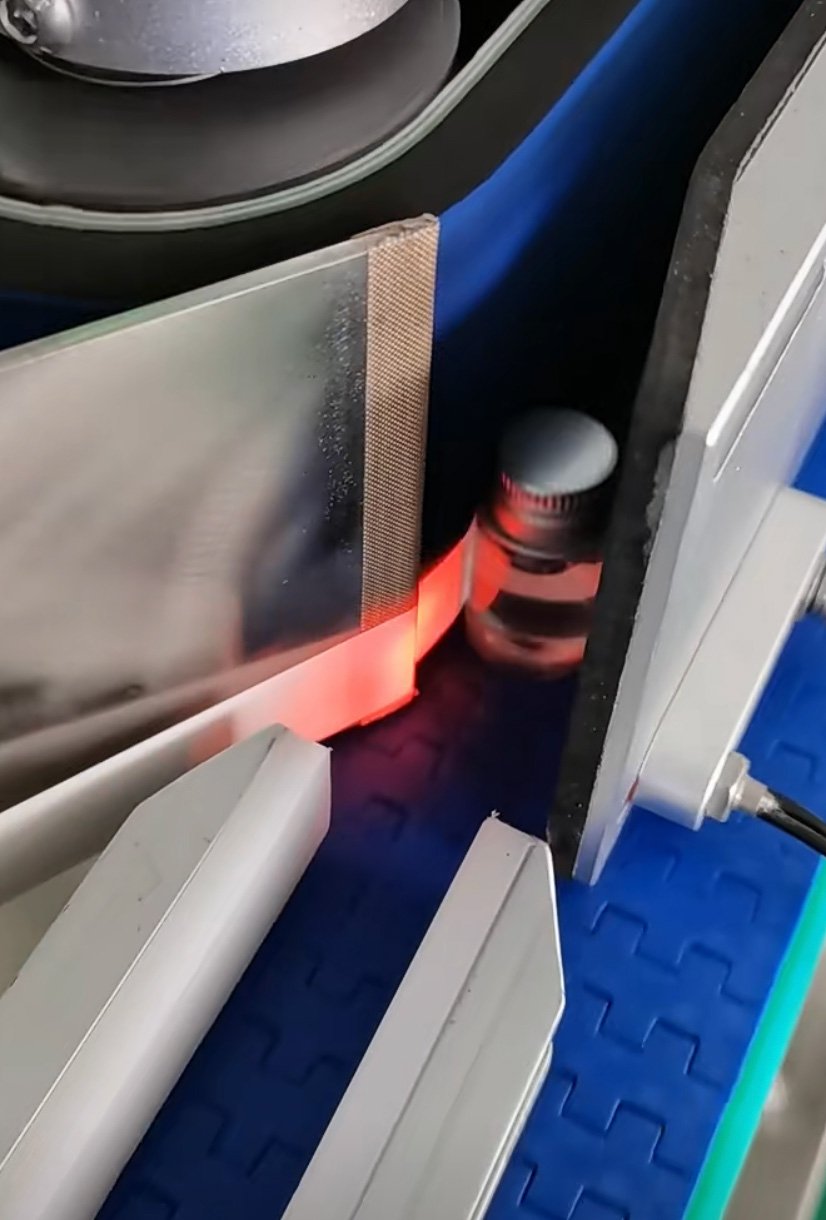

- ボトルが検出されない場合、自動停止機能。ボトルが存在する場合、充填は自動的に再開されます。

- SUS304および316Lステンレス鋼で製造され、最新のGMP基準に完全に準拠しています。

- カスタマイズ可能

- 金型の交換が簡単で、様々な容量のボトル生産に適しています。

Other matched equipments for vial bottle filling production line: bottle feeder, bottle unscrambler, bottle washing, filling, capping, labeling, expire date printing, foil sealing, counting, bottle boxing, sterilizing dryer, etc.