Pharmaceutical Vial Bottle Filling Production Line

Sticlă aplicabilă: 1-50ml

Capacitate de producție: 30-40 sticle/min, poate fi ajustată în funcție de cerințele clientului.

Tensiune: 220V 50Hz

Putere: 2.0KW

Consumul de aer: 0,8-2m³/h 0,3-0,8Mpa

Greutate: 500KG

Dimensions: 2000*1250*1700mm, others parts optional.

Descriere

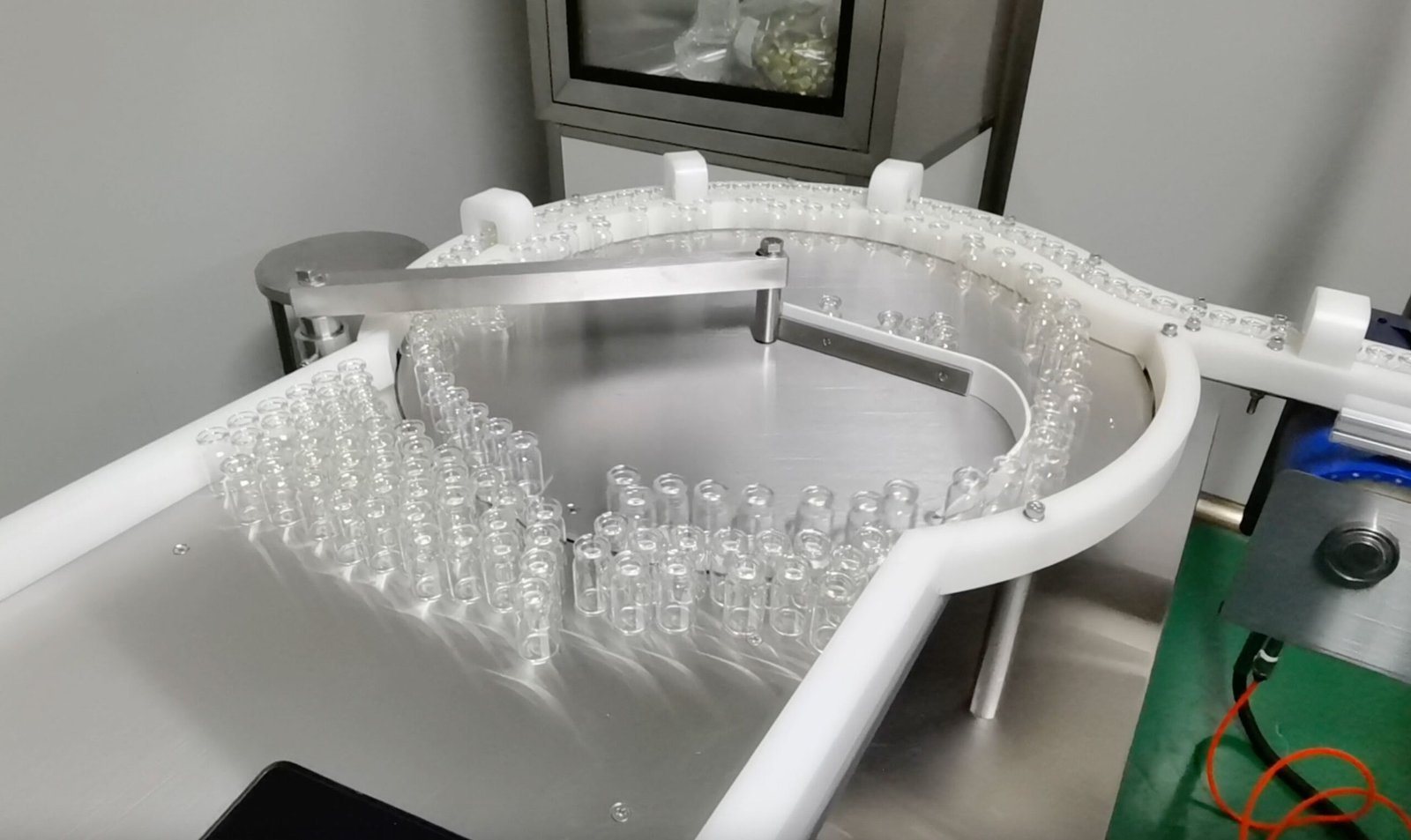

The vial bottle filling production line mainly consists of an automatic bottle washing machine, a tunnel sterilization oven, a vial filling and capping machine, a labeling machine, and other equipment. It adopts PLC control, touch screen operation, and peristaltic pump filling, ensuring high filling accuracy. The entire production line is manufactured in full compliance with the GMP standards and is widely used in the pharmaceutical, food, healthcare, and chemical industries.

Caracteristici:

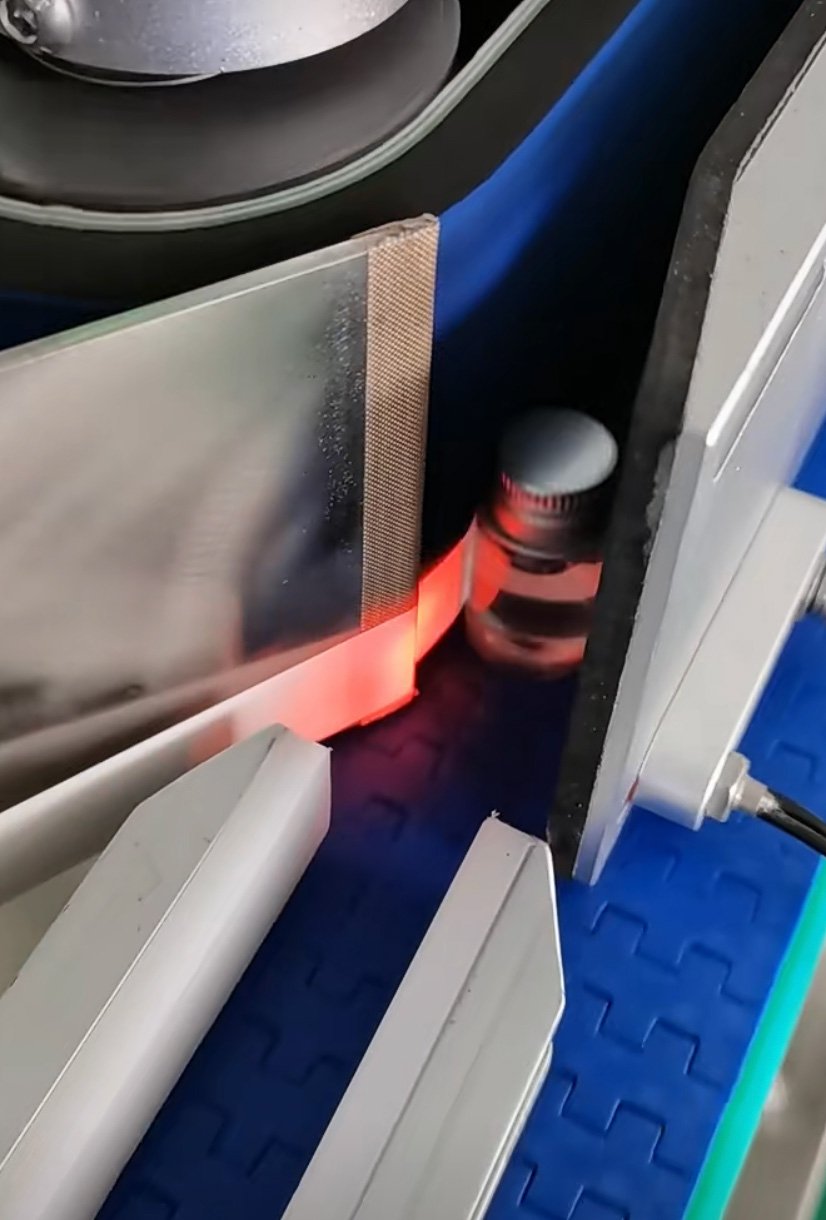

- Indexorul cu came de înaltă calitate asigură o poziționare precisă pentru umplere, astupare și plafonare.

- Umplerea pompei peristaltice cu control prin ecran tactil PLC pentru precizie ridicată și operare ușoară, set de limbi multiple opțional.

- Controlul conversiei frecvenței permite reglarea vitezei.

- Funcție de oprire automată atunci când nu este detectată nicio sticlă; umplerea se reia automat atunci când sunt prezente sticle.

- Produs din oțel inoxidabil SUS304 și 316L, în deplină conformitate cu cele mai recente standarde GMP.

- Personalizabil

- Ușor de înlocuit matrițele, potrivite pentru diferite capacități de producție a sticlelor.

Other matched equipments for vial bottle filling production line: bottle feeder, bottle unscrambler, bottle washing, filling, capping, labeling, expire date printing, foil sealing, counting, bottle boxing, sterilizing dryer, etc.