Turnkey Full Automatic Liquid Filling Production Line

Застосовувана пляшка: 1-500 мл

Виробнича потужність: 30-40 пляшок/хв, 60-80 пляшок/хв, може бути відрегульована відповідно до вимог клієнта.

Напруга: 220В 50Гц

Потужність: 2,0 кВт

Витрата повітря: 0,8-2 м³/год 0,3-0,8 МПа

Вага: 500 кг

Розміри: Розливна машина 2000*1250*1700мм, інші деталі за бажанням.

Опис

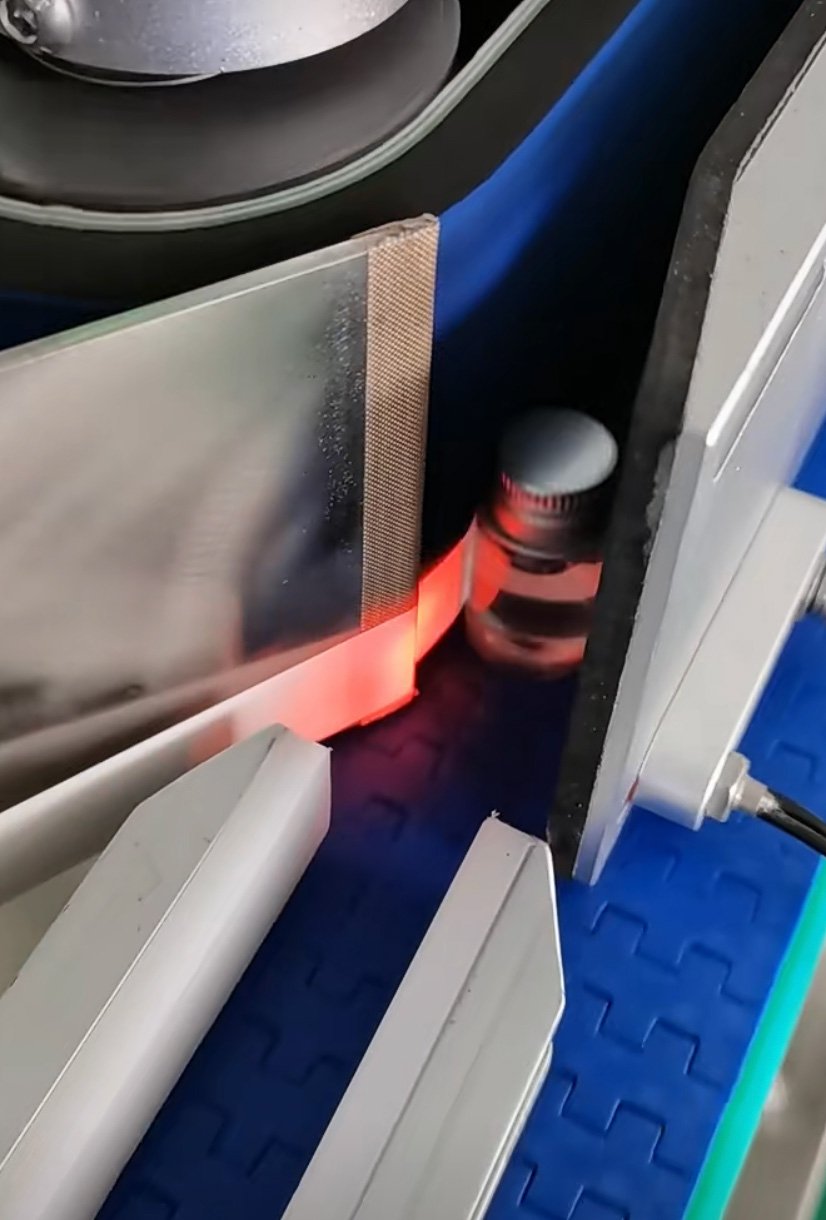

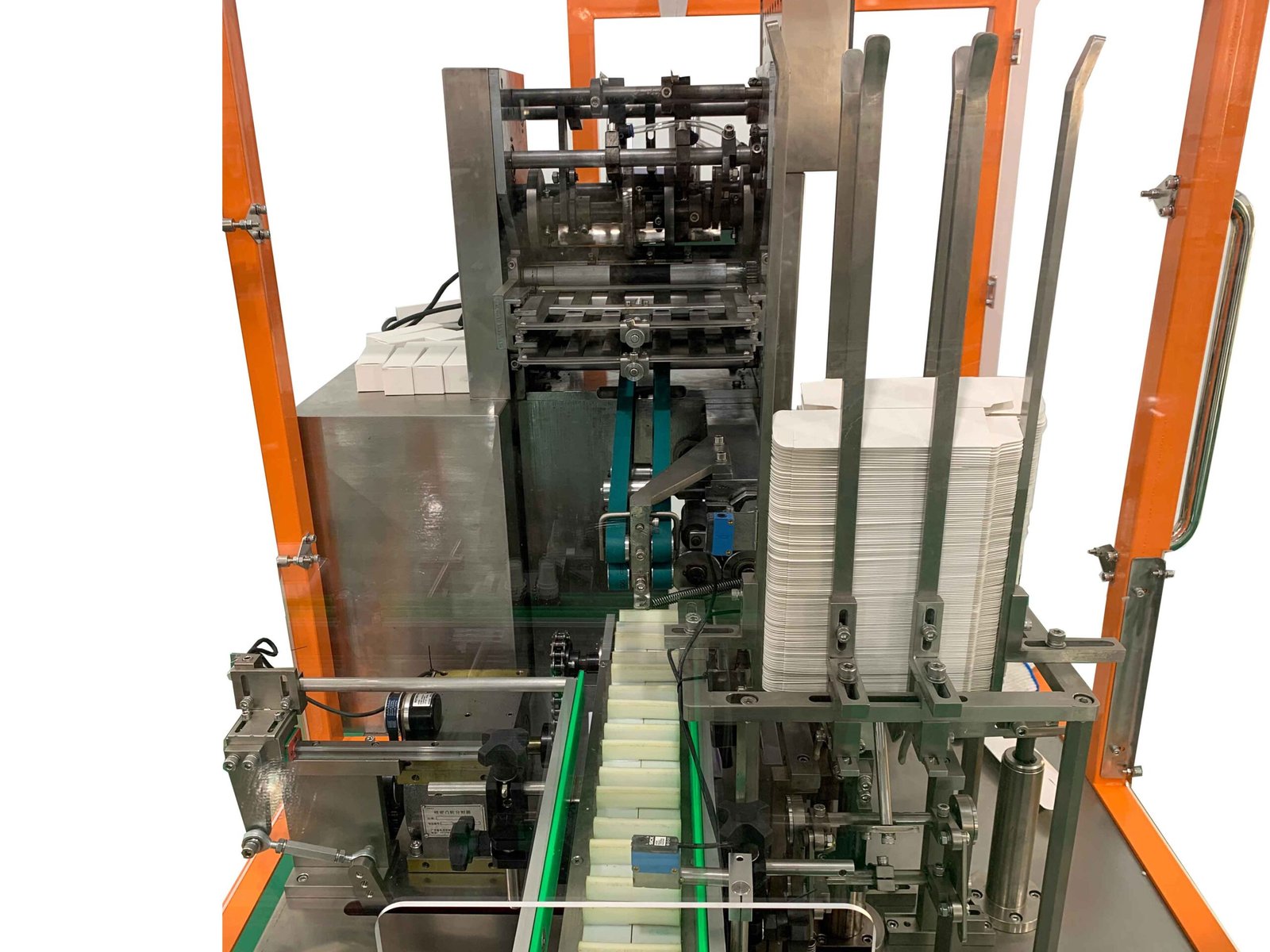

Повністю автоматична лінія для розливу рідини, закупорювання, етикетування та пакування - це інтегроване високоефективне пакувальне рішення, яке широко використовується у фармацевтичній, косметичній, харчовій промисловості та виробництві товарів для здоров'я. Ця модульна виробнича лінія легко поєднує наповнення рідиною, закручування кришок, етикетування та пакування в єдиний налагоджений процес. Лінія управляється системою ПЛК зі зручним сенсорним інтерфейсом, що забезпечує інтелектуальне налаштування параметрів, стабільну роботу та моніторинг у режимі реального часу. Всю систему можна налаштувати відповідно до різних форм, розмірів і вимог до продуктивності пляшок, що робить її ідеальним вибором для автоматизованого великомасштабного виробництва.

Особливості:

- Повністю автоматизований процес від наповнення, закупорювання, етикетування до пакування, що зменшує витрати на робочу силу та підвищує продуктивність.

- Оснащені високоточними перистальтичними або поршневими насосами, що забезпечують точне наповнення без витоків і відходів.

- Підходить для широкого спектру типів і розмірів пляшок. Швидка заміна прес-форми та налаштування параметрів дозволяють здійснювати багатопродуктове та серійне виробництво.

- Управління ПЛК за допомогою сенсорного екрану, зручне управління, гнучкі налаштування параметрів, кілька мов (опціонально).

- Модульна конструкція з невеликою займаною площею, стабільною координацією ліній і простим обслуговуванням.

- Вся машина виготовлена з нержавіючої сталі SUS304/316L, стійкої до корозії і легко миється, відповідає гігієнічним стандартам для фармацевтичної, харчової та косметичної промисловості.

The production line equipments consist: bottle feeder, bottle unscrambler, bottle washing, filling, capping, labeling, expire date printing, foil sealing, counting, bottle boxing, sterilizing dryer, etc.